steel

Proving Its Mettle, Every Day

Amit Metaliks Ltd. (incorporated in 2004) is a premier steel manufacturers in West Bengal, Amit Metaliks Ltd (AML) uses the highest quality of raw materials to ensure quality output of TMT Bar of Grade FE550D. Company is producing TMT Bar using the patented “Thermax” Technology from HSE, Germany.

Amit Metaliks Ltd (AML) is a leading manufacturers of high-quality new-age TMT Rebars under the brand name TRIAM A+ FE 550D. The production capacity is of 0.5 million tonnes of TMT and 0.6 million tonnes of billets. Utilizing a direct charge process from premium-grade billets, these companies have achieved a remarkable milestone of 1 million tonnes in manufacturing capacity. Company has diverse network of channel partners and more than 900 dealer network that are spread across the entire Eastern Region of the country. With our responsiveness and operational excellence we continue to expand further.

Our TMT Bar come in variants of 8 mm to 32 mm and adhere to Indian Standard IS:1786-2008 with its latest amendments for billets IS-14650 and International Standard. The billets produced by the company for re-rolling into steel confirm to Indian Standard IS 2830:2012. .

Amit Metaliks Ltd is Certified company for

ISO 9001: 2015 (Quality Management System);

ISO 45001 :2018 (Occupational Health & Safety Management System); and

ISO 14001: 2015 (Environment Management System)

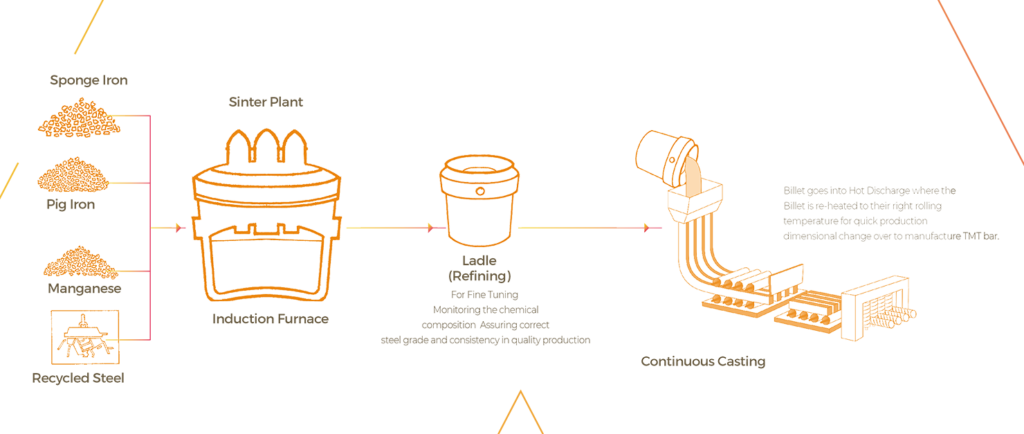

TMT BAR MANUFACTURING PROCESS

To elaborate the process – sponge iron is produced by direct reduction. Upon which it is further melted, refined, deslagged so that the complete removal of impurities is ensured and Steel Billets produced. The billets are further processed in the Thermex processing unit to create TMT bars that are relied upon by the likes of organisations such as SAIL.

Our Brands

Premium brand

It is no ordinary, TMT rebar. Finest manufacturing process, quality inspections at every stage, and a scientifically time-tested rib pattern that leads to better bonding and tolerance distribution ensure that this FE550D is the ultimate star among rebars. Every time you hold an ISI certified TRIAM A+ FE 550D new-age construction rebar in your hand, you feel the presence of the unmatched A+ quality in every square inch of metal.Our premium brand is TRIAM A+ with Fe 550D grade. Click Here For www.triamtmt.com

Regular Material

REGULAR MATERIAL

Trishakti TMT bars are produced through a very rigorous quality control process during its manufacturing process. The state of the art laboratory manned by highly qualified QCA personnel always keep constant vigil during the entire productution process: starting from raw material to finished TMT bar.There is no comprmise with quqlity in every aspect whether raw material, process planning, in-process inspection & final testing.

Few Of Our Clients

TRIAM A+ is approved by Delhi Metro Rail Corporation (DMRC) PWD-West Bengal, Public Health Engineering Dept. West Bengal, West Bengal Medical Services Pvt Ltd., Eastern Coal Field, Haldia Development Authority, Hindustan Copper Limited, Reliance Infrastructure to name a few

About Us

Amit Alliance is spearheading ventures in the infrastructure, mining, metallic and other industries. Partner with us to leverage the Amit Alliance advantage.